- Tokyo

Tokyo National Museum

- Auction House

Sotheby’s London

- Worldwide Museum

National Gallery

- Los Angeles

J.Paul Getty Museum

- San Francisco

Fine Arts Museum

- Moscow

The Pushkin Museum

- San Francisco

North America Asian Art Museum

- Kyoto

Kyoto National Museum

- Tokyo

The National Museum of Western Art

- Taipei

National Palace Museum

- Nanjing

The Nanjing Museum

- Shanghai

Shanghai Museum

- Moscow

Tretyakov Gallery

- Madrid

Museo del Prado

- Rome

Galleria Borghese

- Venice

Gallerie dell’ Accademia

- Montpellier

Musee Fabre

- Beijing

Asia / JapanThe Palace Museum

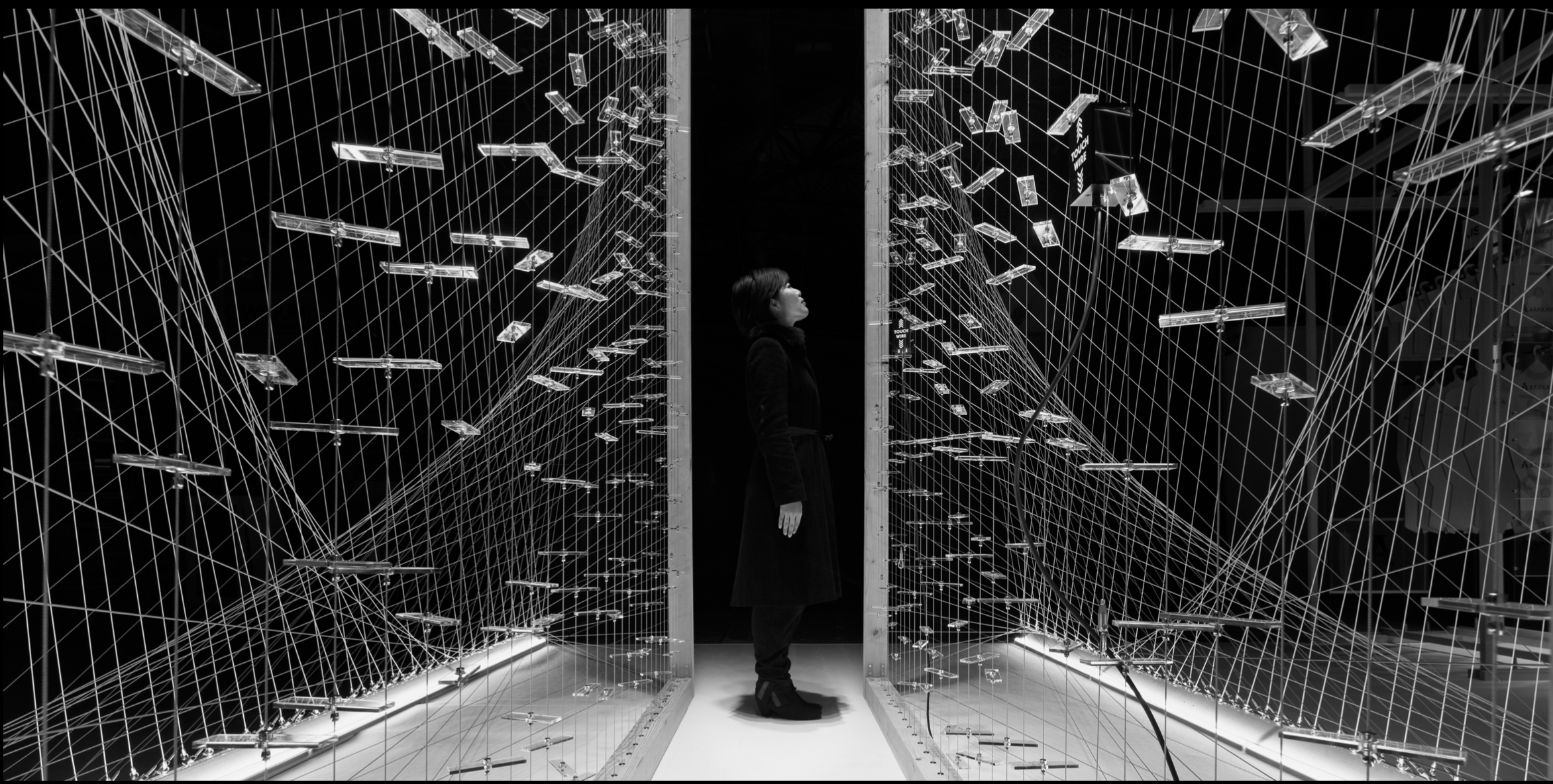

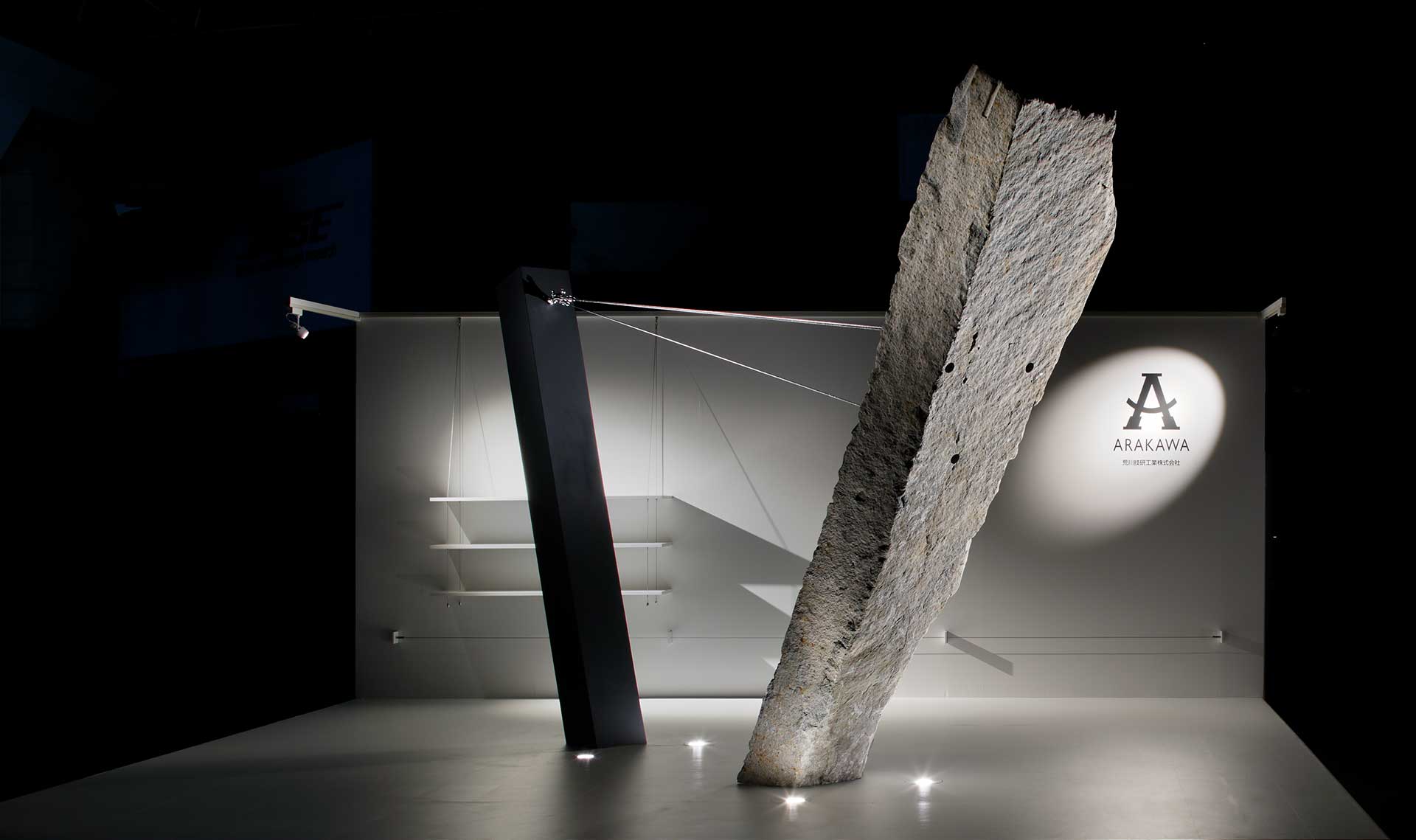

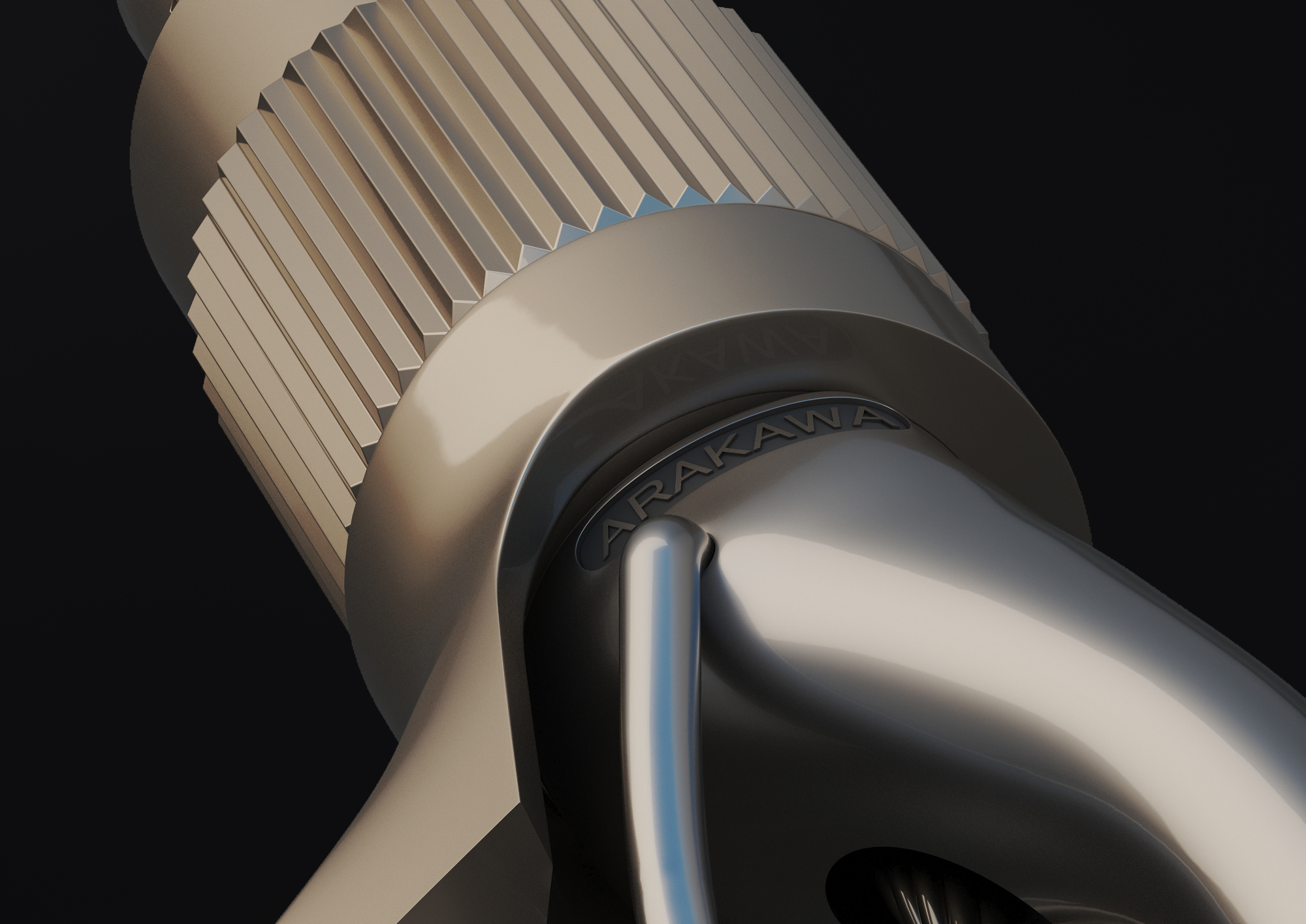

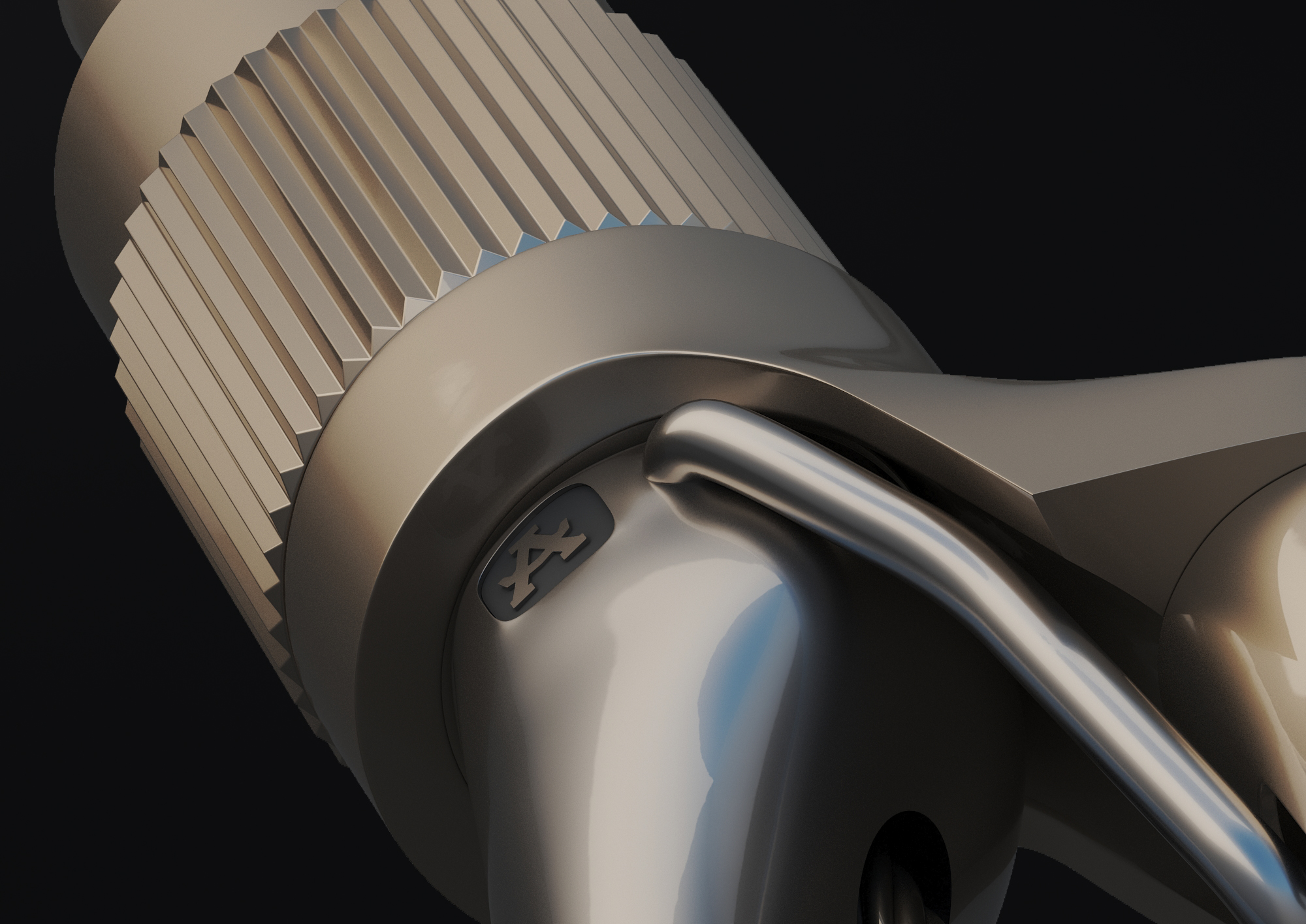

Arakawa

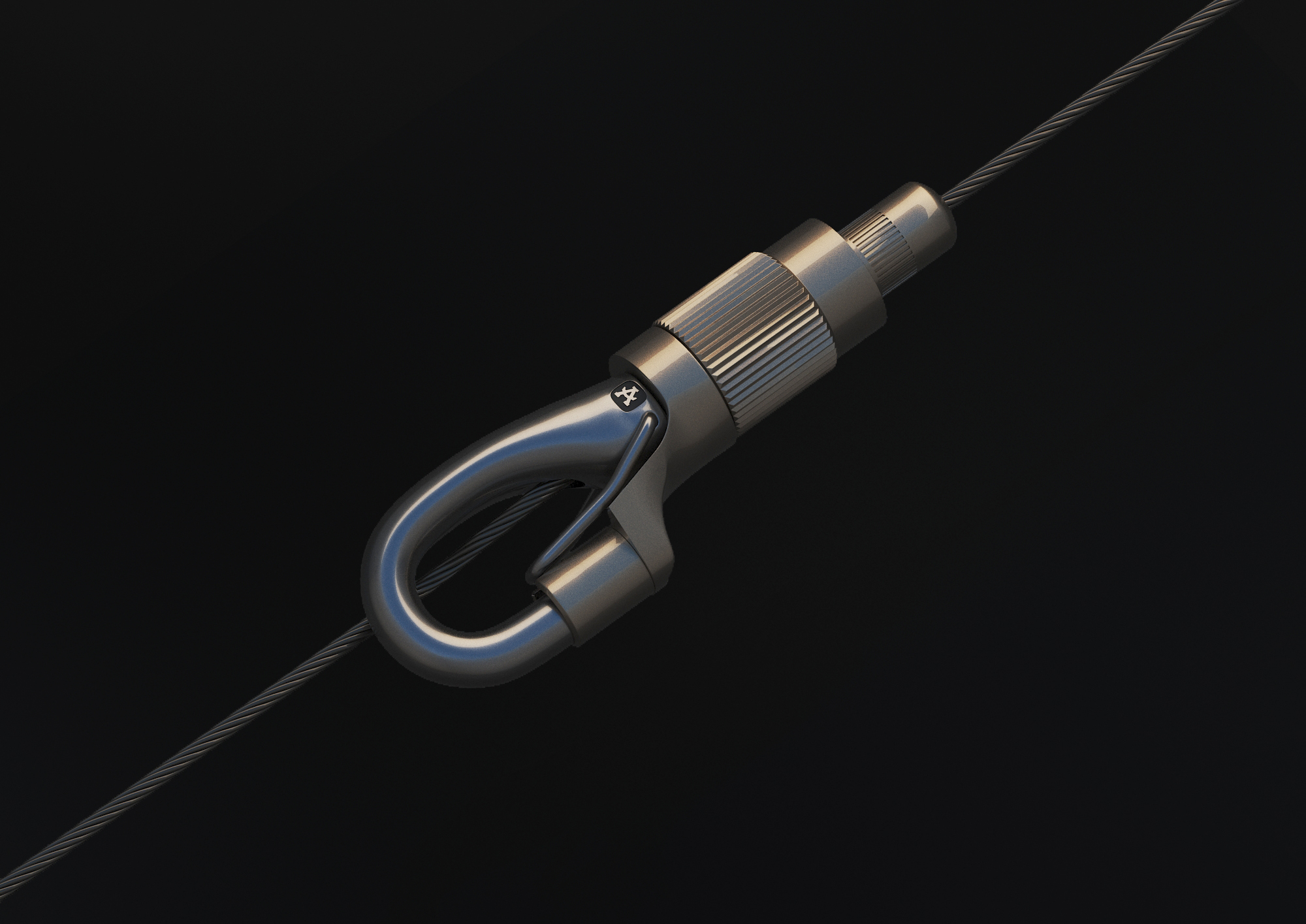

Museums worldwide use the Arakawa hanging systems for artwork installations and presentations because they reliably carry up to 150 kg while blending into the museum architecture and allowing for flexibility.

The Museum Systems

The philosophy of Arakawa: Experience the details

Art is not just seen but experienced. Every detail evokes the story in your mind and adds layers to self-discovery.

Arakawa brings precision engineering details to art. This way, you experience the art piece and its context.

With the capacity to carry up to 150 kg, Arakawa systems set the worldwide standard in the art industry.

All while protecting the European museum ethos and keeping a close eye on aesthetics.

A Symphony of Mastery

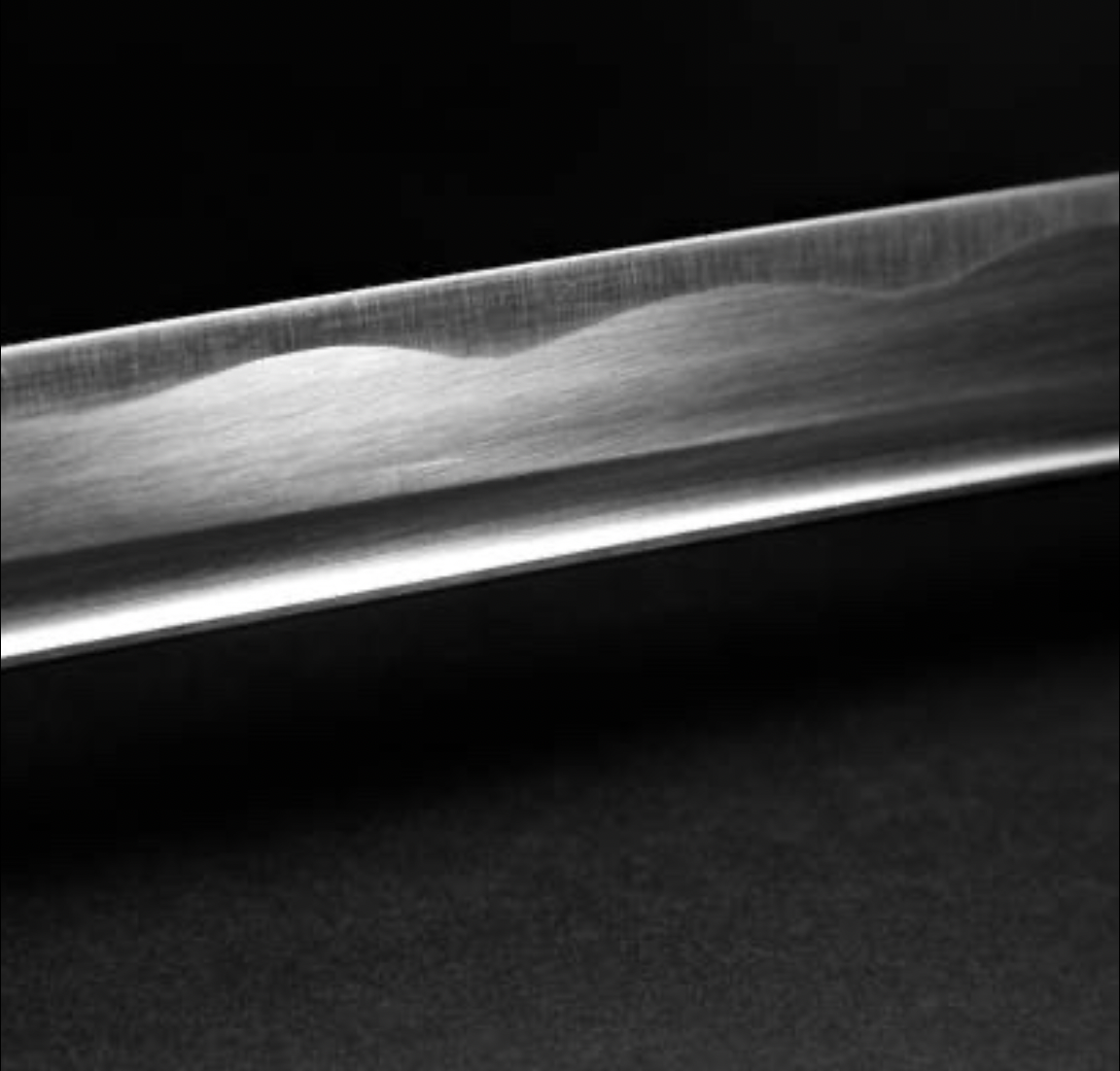

The Art of Display, Redefined Embark on a journey through Arakawa's gallery of museum hanging systems – a testament to precision engineering reminiscent of Japan's legendary katana blades and the meticulous art of bonsai. These systems are not mere fixtures but the canvas on which your curatorial vision thrives.

A Symphony of Mastery

IZBACITI!!!

Tokyo National Museum

Sotheby’s London

National Gallery

J.Paul Getty Museum

Fine Arts Museum

The Pushkin Museum

North America Asian Art Museum

Kyoto National Museum

The National Museum of Western Art

National Palace Museum

The Nanjing Museum

Shanghai Museum

Tretyakov Gallery

Museo del Prado

Galleria Borghese

Gallerie dell’ Accademia

Musee Fabre

Asia / JapanThe Palace Museum

"Art. It's building something purposeful." Dr. Hideo Arakawa

Legacy of Innovation

Legacy of Innovation A Legacy Forged in Precision Delve into the narrative of Arakawa – a legacy backed by patented innovation that has solidified our position as pioneers in museum hanging systems. With a legacy spanning # years, we have stood as the vanguard of innovation, meeting and exceeding the exacting standards of Europe's erudite curators.

Building something that has yet to be built. That's art, right?

Dr. Hideo Arakawa, founder of Arakawa & Co.

I’m an engineer. I may not be an artist by conventional wisdom, but engineering is art. You get to move people, help them achieve something, and discover greatness.

That’s what Arakawa does. It’s the art about the art. Art that protects art.

After completing university, I worked at Hitachi, Ltd. for five years, where I designed chemical machinery and helped set up plants overseas. However, I eventually began to question working for someone else and leaving my job at Hitachi. I decided to pursue a Doctor of Engineering degree in chemical engineering to further my knowledge and expertise. I completed my studies in 1971, and since then, I have applied my advanced knowledge and skills to my professional career.

After that, While working as a consultant for companies like Coca-Cola Japan and Mitsubishi Research Institute, my desire to start my own manufacturing business and create something new in the world grew stronger. Consequently, Arakawa Giken Kogyo was established in 1973.

When the company was founded, it was not particularly noteworthy. My graduate school professor asked me to assist a small to medium-sized company located in Chiba. I designed and created a high-precision wire processing machine, but it never sold, leaving me feeling lost. However, I became intrigued by developing equipment for tensioning wire without slack, so I tackled the problem head-on. I decided to create a wire tensioning tool that had never been developed.

Arakawa Giken Kogyo was the first to commercialize the “Hand Puller (HP-1)” with its unique features. This wire can be easily attached and detached with one touch without pre-cutting. It is also lightweight and easy to use. Despite limited uses and high costs initially, we achieved good results after delivering the product to Kandenko. We began exploring the possibility of further uses and applications. Thanks to its innovative design and practicality, the Hand Puller is still being sold today.

In 1980, an advanced and compact wire gripper, an improved version of the HP-1, was showcased at the “Japan Shop” store supplies exhibition. This exhibition generated a lot of interest, and we received multiple inquiries regarding the wire tensioning tool. As a result, wire tensioning tools became popular for various applications, including museum displays and exhibitions.

First Tokyo. Then, the world.

Mr Kondo, collaborator with Arakawa

What kind of work did Mr. Kondo initially do?

- Kondo worked at the Tokyo branch of a specific company, and since the 1960s, they have been handling large quantities of materials for high-rise buildings, such as ceilings, walls, floors, etc. Based on that knowledge, they came across Picture Rail while thinking about what they could do next. In 1982, Kunio Maekawa Architects, working at the Miyagi Prefectural Museum of Art, requested a new picture rail, and they asked Arakawa Giken Kogyo to manufacture it. Until then, Japanese art museums had used stage rails, which were used for stage curtains and were repurposed from curtain rails that had a hefty load capacity.

How did you meet Arakawa Giken Kogyo?

- At the time, Kondo first learned that Mr. Arakawa had exhibited a new type of grip at an exhibition called Japan Shop, and they contacted him for the first time. They thought of a similar mechanism but couldn’t clear it, so they looked at the grip and had it do everything. The Miyagi Prefectural Museum of Art uses metal fittings called “FZ-20.” After that, as the number of museums increased across Japan, the grips manufactured by Mr. Arakawa on an OEM basis became widely used. What used to be zero became 10, then 100, then 1,000, and then spread worldwide. They were confident that this would sell. The effect of the Miyagi Prefectural Museum of Art was enormous.

Why did picture rails become so popular?

- Kondo proposed a system with rails attached to the ceiling, walls, hangers, and attachments. Up until then, it was common practice to attach frame holders to the wall and hang the picture hanging clasps from there, but the main reason was that they didn’t want to stain the walls. Mr. Arakawa’s metal fittings are used in the State Tretyakov Gallery in Russia (delivered in 1993), the Metropolitan Museum of Art in New York, the British Museum in England, and the National Palace Museum in Taipei.

- Arakawa Giken Kogyo’s unique technology allows it to be fixed by simply inserting a wire into the grip.

- Kondo initially used a loop wire, and a hook was hung on the loop. What Mr. Arakawa developed is called a one-touch wire, which is fixed by inserting the end of the wire into the grip. Each has its characteristics, so there was an advantage in having two types available. When commercializing a rail system using this grip, they considered safety, workability, durability, design, low cost, and no damage to walls. Regarding rail specifications, it was also helpful that they worked on ceiling systems for high-rise buildings for many years.

- Mr. Kondo established A-One Ltd. in 1994. What kind of activities have you been involved in since then?

- Kondo spent a month in the United States before establishing A-One Ltd. and had the opportunity to visit various art galleries, museums, and construction sites. Then, they learned that the world has yet to see a rail system. After the company was established, they could use their previous experience to study various things, not just picture rails. It was a time when the way architecture was being done was undergoing significant changes, and they worked on many projects with Mr. Arakawa. A-One’s delivery destinations included the Tokyo National Museum Heiseikan, Tokyo Museum of Contemporary Art, National Museum of Western Art, Ueno Royal Museum, and Tokyo University of the Arts. They have been involved in the hardware industry for 27 years at A-One and 66 years.

What do you think about the possibilities of picture rails in the future?

- The Kondo wire hanging system can be used for various purposes, such as mirrors and televisions. It will also help prevent furniture from falling over as an earthquake measure. From now on, it will be essential to consider how to use existing buildings, and since there are many high-rise condominiums in particular, countermeasures are necessary. Kondo comes from Awaji Island, and the Great Hanshin-Awaji Earthquake occurred right after they founded A-One, so they are seriously considering that.

The new standard for Art Museums

Mr Yoshioka, Sales Manager of Arakawa

Mr. Yoshioka, when did you start working with picture rails?

- Yoshioka: I started working for a company in Kansai in 1979 and was transferred to the Tokyo office in 1987. This office had a business relationship with Arakawa Giken Kogyo, and they were already delivering picture rails to museums and other places by mixing metal fittings made by Arakawa with different parts. Over time, as the number of museums increased across Japan, I continued to be involved in this work. I left that company in 2005 and started working for Arakawa in 2008, and I continue to work with Picture Rail to this day.

Please explain how the picture rail works.

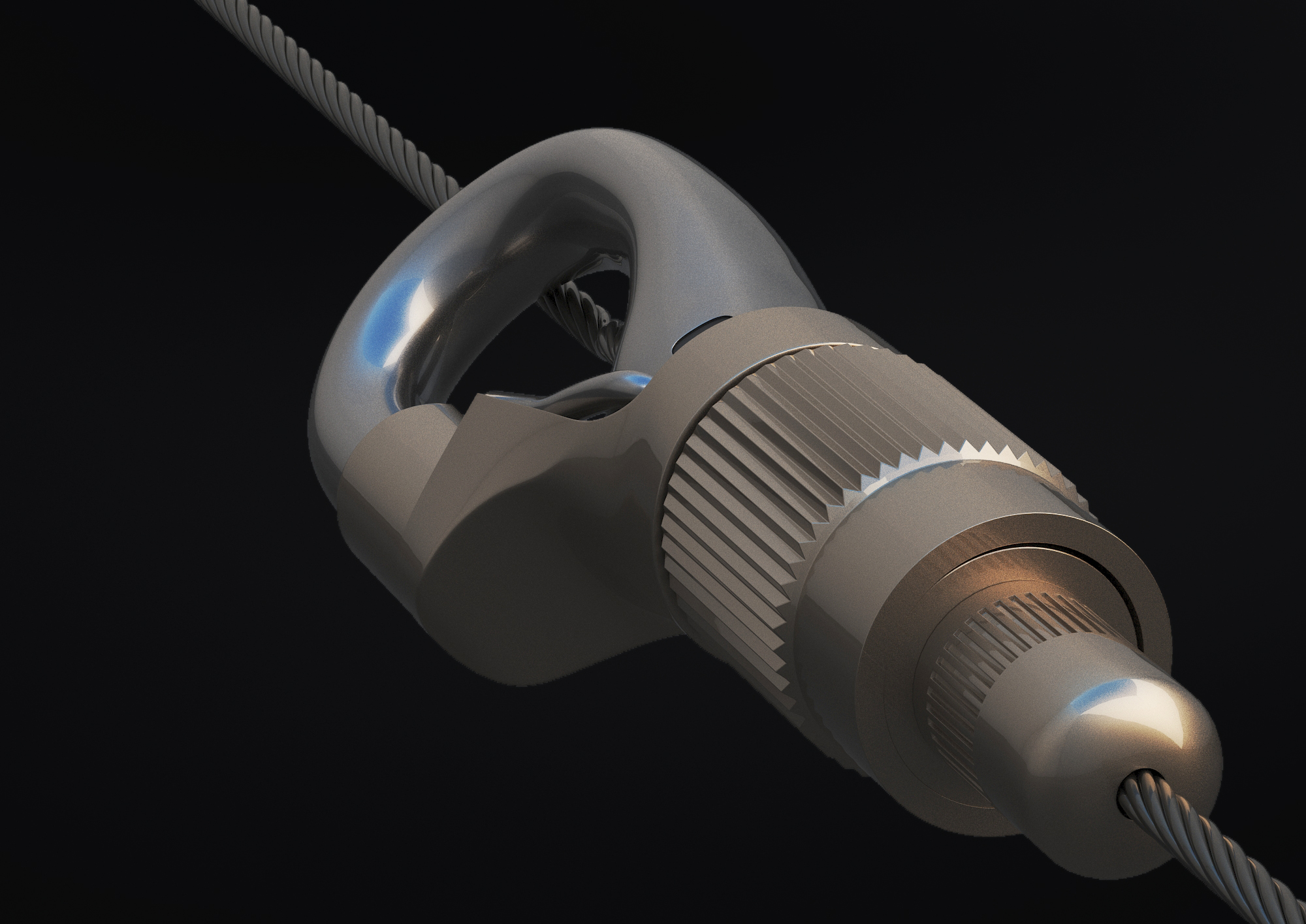

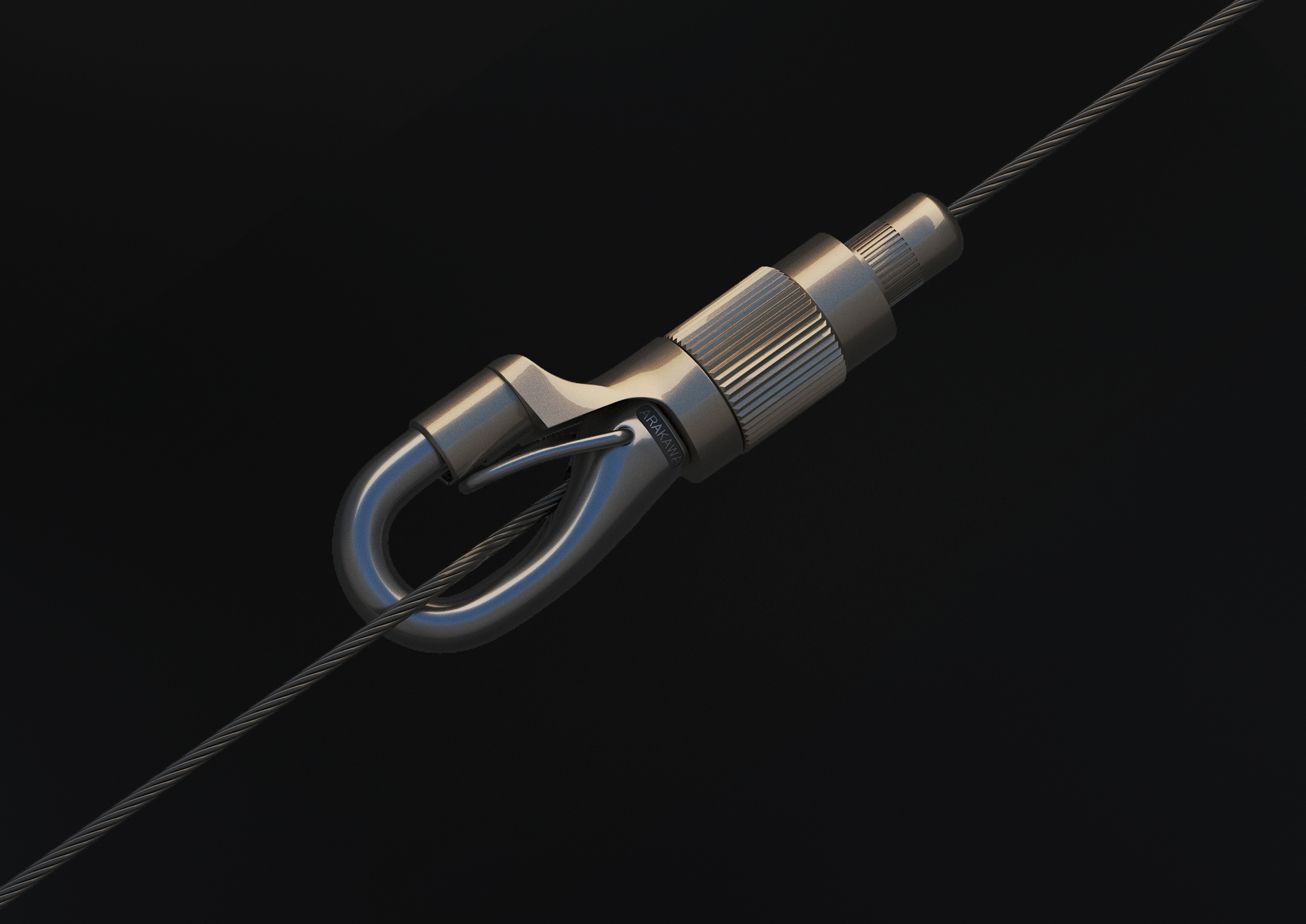

- Yoshioka: Picture Rail is more accurately called a picture hanging system, comprising four parts: the rail, rail attachment, wire, and hanger. In this system, the hanger, which is a hook-type gripper, is an important part that has built-in gripper functions for attaching, detaching, fixing, and moving the wire. Each of these four parts has its strength, and the system’s total performance for hanging paintings is the allowable load. In the 1970s, Arakawa was the only company that could make grippers operated with one touch. Other manufacturers’ products also used Arakawa’s metal fittings.

Why was Arakawa’s gripper so good?

- Yoshioka: There are three balls inside the metal fittings, and the mechanism that uses their movement to secure the wire was developed independently by the current chairman of Arakawa. There are several ways to ensure the wire, but we decided this was the best because of its safety and ease of operation. Insert the tip of the wire into the metal fitting, and it will stay in place. Since the number of parts is reduced, failures are less likely to occur, and costs are reduced. Arakawa’s grip-based rail system has become.

So, the ties between Arakawa Giken Kogyo and the museum are strong.

- Yoshioka: In Japan, from the 1980s to the 1990s, public art museums were created nationwide as a national policy. For architects, designing a museum is a once-in-a-lifetime difficult task. That’s why I’m very particular about it. Therefore, a high-performance picture rail was needed to avoid interfering with the design. It is challenging to meet the demands, but on the other hand, thanks to the number of products we have increased in this way, we have increased the variety of products. In particular, Japanese art museums often have special exhibitions that bring in works from overseas, and exhibits change frequently, so picture rails that can easily accommodate the position and size of works are essential. Picture rails became popular in ordinary households probably due to the increasing number of people who have more opportunities to view paintings in museums and want to do so at home. It spread from housing for foreigners.

Mr. Yoshioka, what aspects of your work have you found rewarding?

- Yoshioka: What was interesting was working with art museums. Products for museums are iconic in any display. Since we are hanging costly items, we cannot do this without a proven track record and trust. I worked with famous people such as Kisho Kurokawa and Kiyonori Kikutake, and I also have fond memories of my interactions with the curators who selected the products. It was a very unusual experience. However, because the scale of the work is large, it takes about ten years from the time the museum is conceptualized, the budget is decided, the basic plan and design are completed, and the facility is completed. When we start hearing about plans, we must visit the preparation room and communicate our achievements.

What kind of wire systems will Arakawa Giken Kogyo create in the future?

- It has been more than 40 years since the Museum of Art has been using such a system, but I do not see many signs that something fundamentally different will emerge. Currently, it is only used to display two-dimensional works, but it can also be used to display three-dimensional works by floating boxes with wire. There is potential for such usage. I also think that the gripper, the heart of the system, can be used in various ways in architectural spaces, such as stretching wire horizontally and securing multiple objects.

Beginning of Arakawa

After graduating from university, I got a job at Hitachi, Ltd., where I continued to work for five years, designing chemical machinery and setting up plants overseas. Eventually, he began to question the idea of being hired and quit his job at Hitachi. To further his knowledge, he entered graduate school to study chemical engineering, which he completed in 1971 with a Doctor of Engineering degree.

After that, while working as a consultant for companies such as Coca-Cola Japan and Mitsubishi Research Institute, my desire to start my own manufacturing business and create something that didn’t exist in the world grew stronger. Arakawa Giken Kogyo was established in 1973.

However, when the company was founded, there was nothing special to do. My professor from graduate school asked me to provide guidance to a small to medium-sized company in Chiba. After designing and prototyping a high-precision wire processing machine, it never sold and I was at a loss.When I became interested in equipment for tensioning wire (stretching wire without slack), I set out to solve the problem. , I decided to develop a wire tensioning tool that had never existed before.

The wire can be attached and detached with one touch, the wire can be wired without pre-cutting, and it is lightweight and easy to use. The “Hand Puller (HP-1)” with these characteristics was first commercialized by Arakawa Giken Kogyo, and it continues to be sold today. We started delivering the product to Kandenko and achieved good results, but at first it had limited uses and was expensive, so we began exploring the possibility of further uses.

In 1980, a wire gripper, an improved and smaller version of the HP-1, was exhibited at the store supplies exhibition “Japan Shop”. Then we received several inquiries. This led to the spread of wire tensioning tools to a variety of uses, including various displays and exhibitions at museums.

Arakawa's new grip changed my life

What kind of work did Mr. Kondo originally do?

Kondo I worked at the Tokyo branch of a certain company, and since the 1960s we had been handling large quantities of materials for ceilings, walls, floors, etc. for high-rise buildings. When I was thinking about what I could do next based on that knowledge, I came across Picture Rail. In 1982, Kunio Maekawa Architects, who was working on the Miyagi Prefectural Museum of Art, requested a new picture rail, and I asked Arakawa Giken Kogyo to manufacture it. Until then, Japanese art museums had used stage rails, which were used for stage curtains, and were repurposed from curtain rails that had a large load capacity.How did you meet Arakawa Giken Kogyo?

At the time of Kondo, I first learned that Mr. Arakawa had exhibited a new type of grip at an exhibition called Japan Shop, and contacted him for the first time. I was thinking of a similar mechanism, but I couldn’t clear it, so I decided to look at the grip and have it do everything. The Miyagi Prefectural Museum of Art uses metal fittings called “FZ-20.” After that, as the number of museums increased across Japan, the grips manufactured by Mr. Arakawa on an OEM basis became widely used. What used to be 0 became 10, then 100, then 1000, and then spread all over the world. We were confident that this would sell. The effect of the Miyagi Prefectural Museum of Art was enormous.Why did picture rails become so popular?

Kondo: Up until then, it was common practice to attach frame holders to the wall and hang the picture hanging clasps from there, but the main reason was that we didn’t want to stain the walls. In contrast, the picture rail that I proposed is a system that includes rails that attach to the ceiling and walls, as well as hangers and attachments. I learned about the good and bad points of previous picture rails, and then drew and completed my own drawings. Mr. Arakawa’s metal fittings are used in the State Tretyakov Gallery in Russia (delivered in 1993), the Metropolitan Museum of Art in New York, the British Museum in England, and the National Palace Museum in Taipei.Arakawa Giken Kogyo has a unique technology that allows it to be fixed by simply inserting a wire into the grip.

Kondo: Originally, there was a loop wire, and a hook was hung on the loop. What Mr. Arakawa developed is called a one-touch wire, and it is fixed by inserting the end of the wire into the grip. Each has its own characteristics, so there was an advantage in having two types available. When commercializing a rail system using this grip, we considered safety, workability, durability, design, low cost, and no damage to walls. When it came to things like rail specifications, it was also helpful that I had worked on ceiling systems for high-rise buildings for many years.Mr. Kondo established A-One Ltd. in 1994. What kind of activities have you been involved in since then?

Kondo: Before that, I spent a month in the United States and had the opportunity to visit various art galleries, museums, and construction sites. Then I learned that the world has yet to see a rail system. After the company was established, I was able to make use of my previous experience and study a variety of things, not just picture rails. It was a time when the way architecture was being done was undergoing major changes, and I worked on many projects with Mr. Arakawa. A-One’s delivery destinations included the Tokyo National Museum Heiseikan, Tokyo Museum of Contemporary Art, National Museum of Western Art, Ueno Royal Museum, and Tokyo University of the Arts. I have been involved in the hardware industry for 27 years at A-One and 66 years.What do you think about the possibilities of picture rails in the future?

The Kondo wire hanging system can be used for a wide range of purposes, such as mirrors and televisions. It will also help prevent furniture from falling over as an earthquake measure. From now on, it will be important to consider how to use existing buildings, and since there are many high-rise condominiums in particular, countermeasures are necessary. I’m from Awaji Island, and the Great Hanshin-Awaji Earthquake occurred right after I founded A-One, so I’m thinking about that particularly seriously.The new standard for art museums

Mr. Yoshioka, when did you start working with picture rails?

Yoshioka: I started working for a company in Kansai in 1979, and was transferred to the Tokyo office in 1987. This office had a business relationship with Arakawa Giken Kogyo, and they were already delivering picture rails to museums and other places by mixing metal fittings made by Arakawa with other parts. Over time, as the number of museums increased across Japan, I continued to be involved in this work. I left that company in 2005, and started working for Arakawa in 2008, working with Picture Rail to this day.Please explain how the picture rail works.

Yoshioka Picture Rail is more accurately called a picture hanging system, and it is made up of four parts: the rail, rail attachment, wire, and hanger. In this system, the hanger, which is a hook-type gripper, is an important part that has built-in gripper functions for attaching, detaching, fixing, and moving the wire. Each of these four parts has its own strength, and the total performance of the system for hanging paintings is the allowable load. In the 1975s, Arakawa was the only company that could make grippers that could be operated with one touch. Other manufacturers’ products also used Arakawa’s metal fittings.Why was Arakawa’s gripper so good?

There are three balls inside the Yoshioka metal fittings, and the mechanism that uses their movement to secure the wire was developed independently by the current chairman of Arakawa. There are several ways to secure the wire, but we decided this was the best because of its safety and ease of operation. Insert the tip of the wire into the metal fitting and it will stay in place. Since the number of parts is reduced, failures are less likely to occur and costs are reduced. Arakawa’s grip-based rail system has becomeSo the ties between Arakawa Giken Kogyo and the museum are strong.

Yoshioka: In Japan, from the 1980s to the 1990s, public art museums were created across the country as a national policy. For architects, designing a museum is a once-in-a-lifetime difficult task. That’s why I’m very particular about it. Therefore, a picture rail that had high performance and did not interfere with the design was needed. It is difficult to meet the demands, but on the other hand, thanks to the number of products we have increased in this way, we have been able to increase the variety of products. In particular, Japanese art museums often have special exhibitions that bring in works from overseas, and exhibits change frequently, so picture rails that can easily accommodate the position and size of works are essential. The reason why picture rails became popular in ordinary households is probably due to the increasing number of people who have more opportunities to view paintings in museums and want to do so at home. It spread from housing for foreigners.Mr. Yoshioka, what aspects of your work have you found rewarding?

Yoshioka : What was interesting was working with art museums. Products for museums are iconic in any display. Since we are hanging extremely expensive items, we cannot do this unless we have a proven track record and trust. I worked with famous people such as Kisho Kurokawa and Kiyonori Kikutake, and I also have fond memories of my interactions with the curators who actually selected the products. It was a very unusual experience. However, because the scale of the work is large, it takes about 10 years from the time the museum is conceptualized, the budget is decided, the basic plan and design are completed, and the facility is completed. From the time we start hearing about plans, we must visit the preparation room and communicate our achievements.What kind of wire systems will Arakawa Giken Kogyo create in the future?

It has been more than 40 years since the Yoshioka Museum of Art has been using such a system, but I don’t see many signs that something fundamentally different will emerge. Currently, it is only used to display two-dimensional works, but it can also be used to display three-dimensional works by floating boxes with wire. There is potential for such usage. I also think that the gripper, which is the heart of the system, can be used in a wide variety of ways in architectural spaces, such as stretching wire horizontally and securing various objects.Our Projects

Safeguarding art worldwide

Discover the seductive interplay of artwork and Arakawa solutions in some of the world's most sophisticated museums.

Tokyo National Museum

Sotheby’s London

National Gallery

J.Paul Getty Museum

Fine Arts Museum

The Pushkin Museum

North America Asian Art Museum

Kyoto National Museum

The National Museum of Western Art

National Palace Museum

The Nanjing Museum

Shanghai Museum

Tretyakov Gallery

Museo del Prado

Galleria Borghese

Gallerie dell’ Accademia

Musee Fabre

Asia / JapanThe Palace Museum

Up to 150 kg of weight per meter.

Art knows no limit, and neither should you.

With Arakawa's hanging systems, crafted to perfection like traditional Katanas, you can safely hang everything

— from susceptible impressionist paintings to surrealist concrete block installations.

Testimonials

Contact us

Bring the exclusive spirit of Arakawa

to your museum

Get personalized Arakawa hanging solutions and ensure your artwork and art installations get extra safety and flexibility. Talk to our art connoisseurs and receive tailored recommendations that those with the finest taste will surely recognize.